2 ½” Silicone Extrusion Line w/ Continuous Curing Oven, Item # 1883

1" - 3" Extruders, Extrusion Lines, Curing Lines

2 ½” Silicone Extrusion Line w/ Continuous Curing Oven, Item # 1883

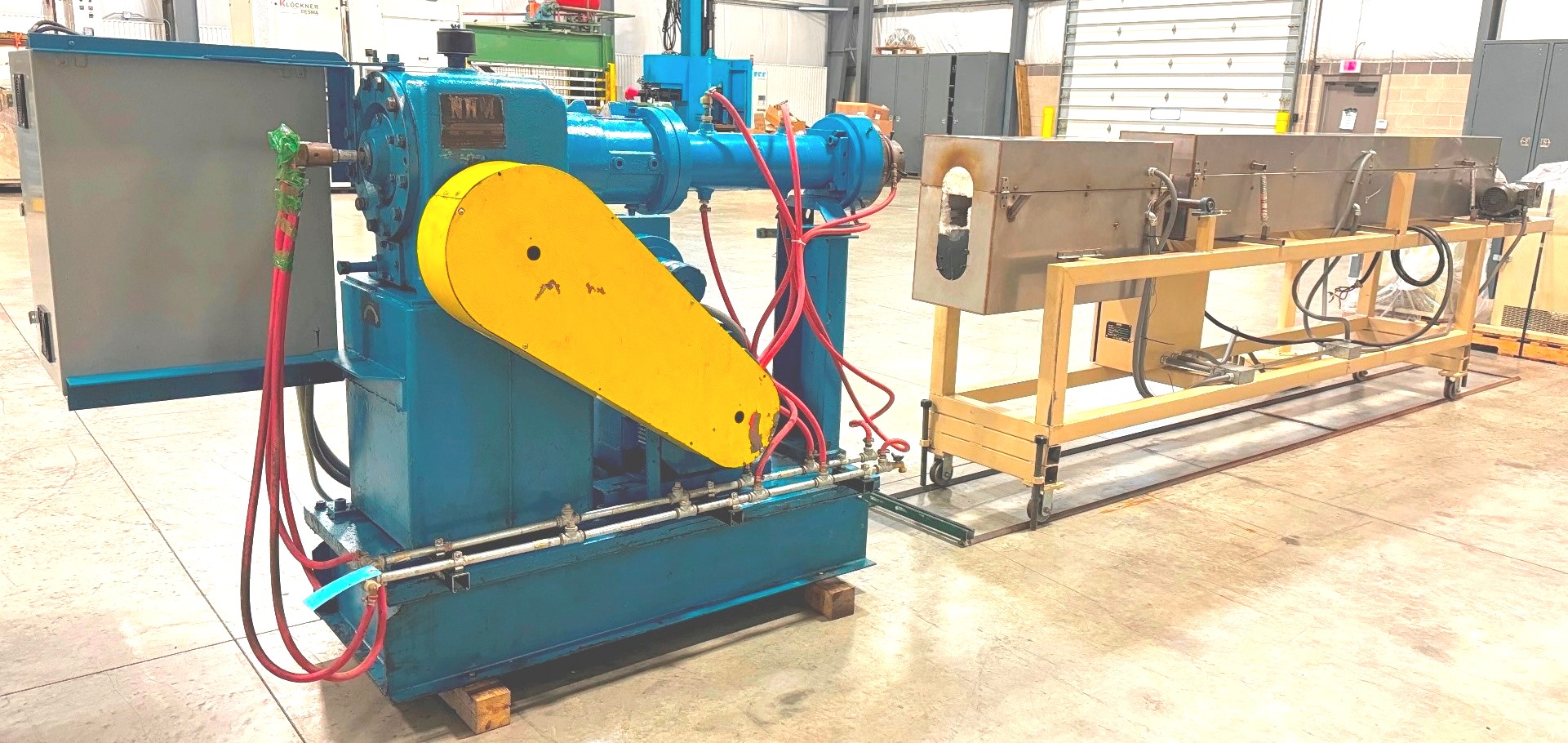

- 2 ½” NRM extruder

- cold feed

- power roll feed

- 12:1 L/D

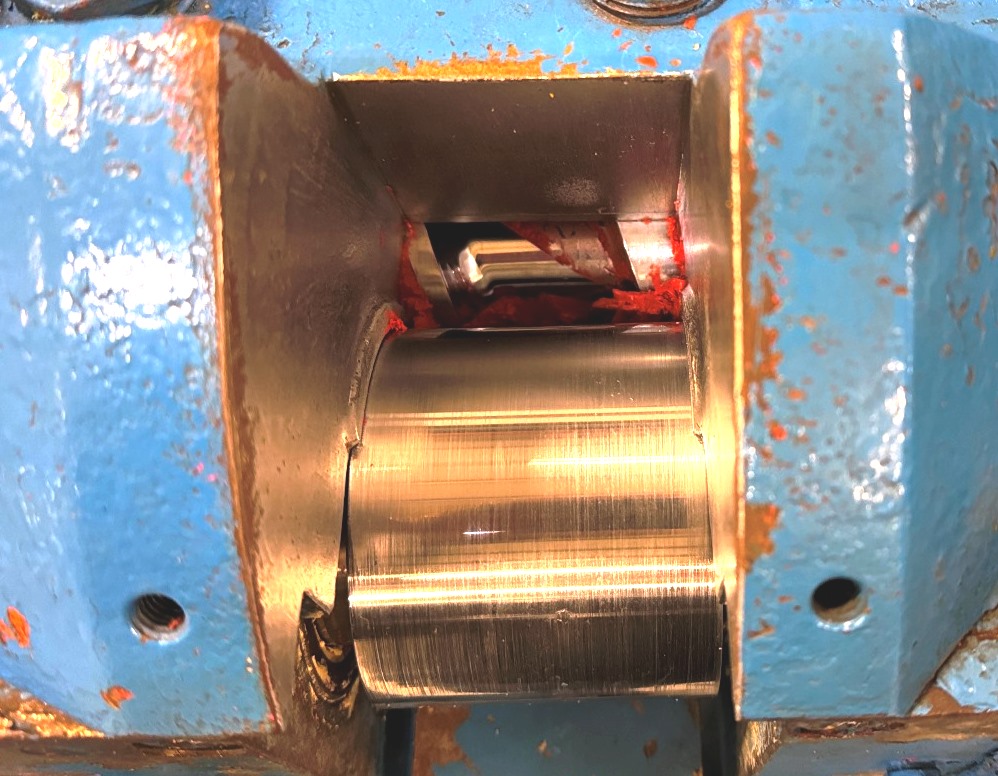

- cored silicone screw

- jacketed barrel for cooling, cored screw for cooling via rotary joint

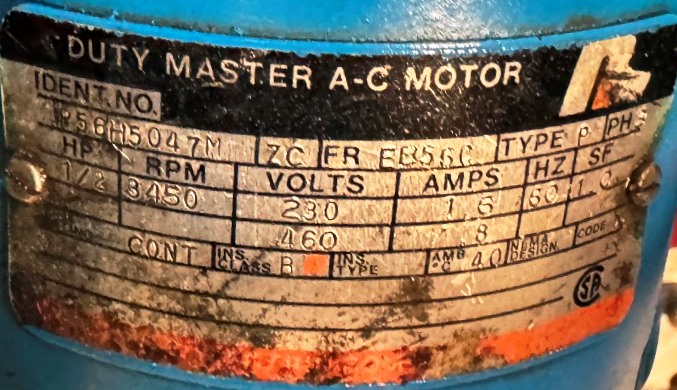

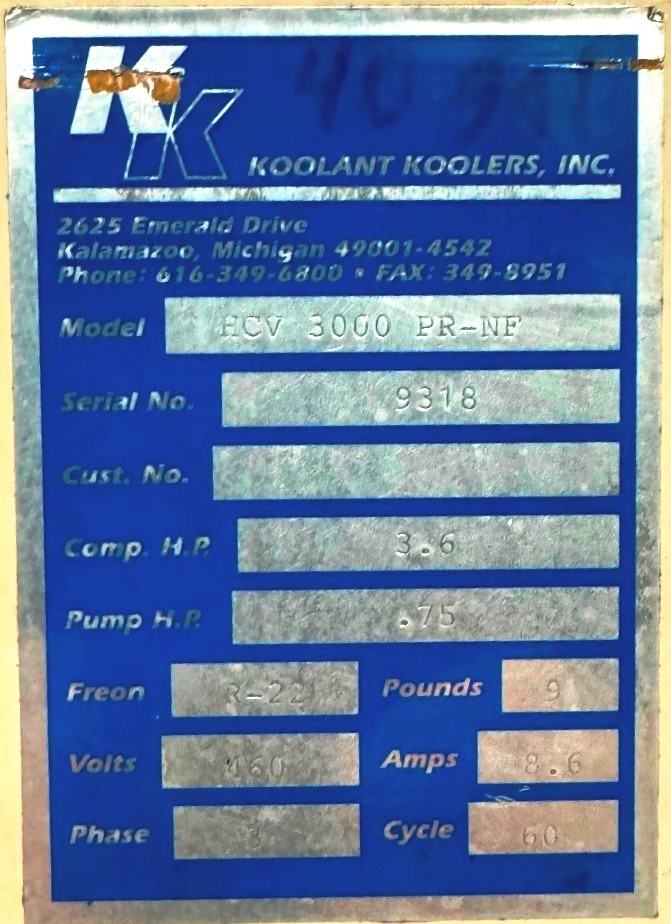

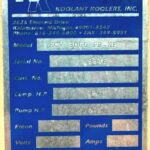

- 3 Ton Koolant Koolers Chiller

- heavy duty gear reducer

- belt driven

- Reliance 40 hp dc motor

- variable speed

- Bardac digital SCR drive

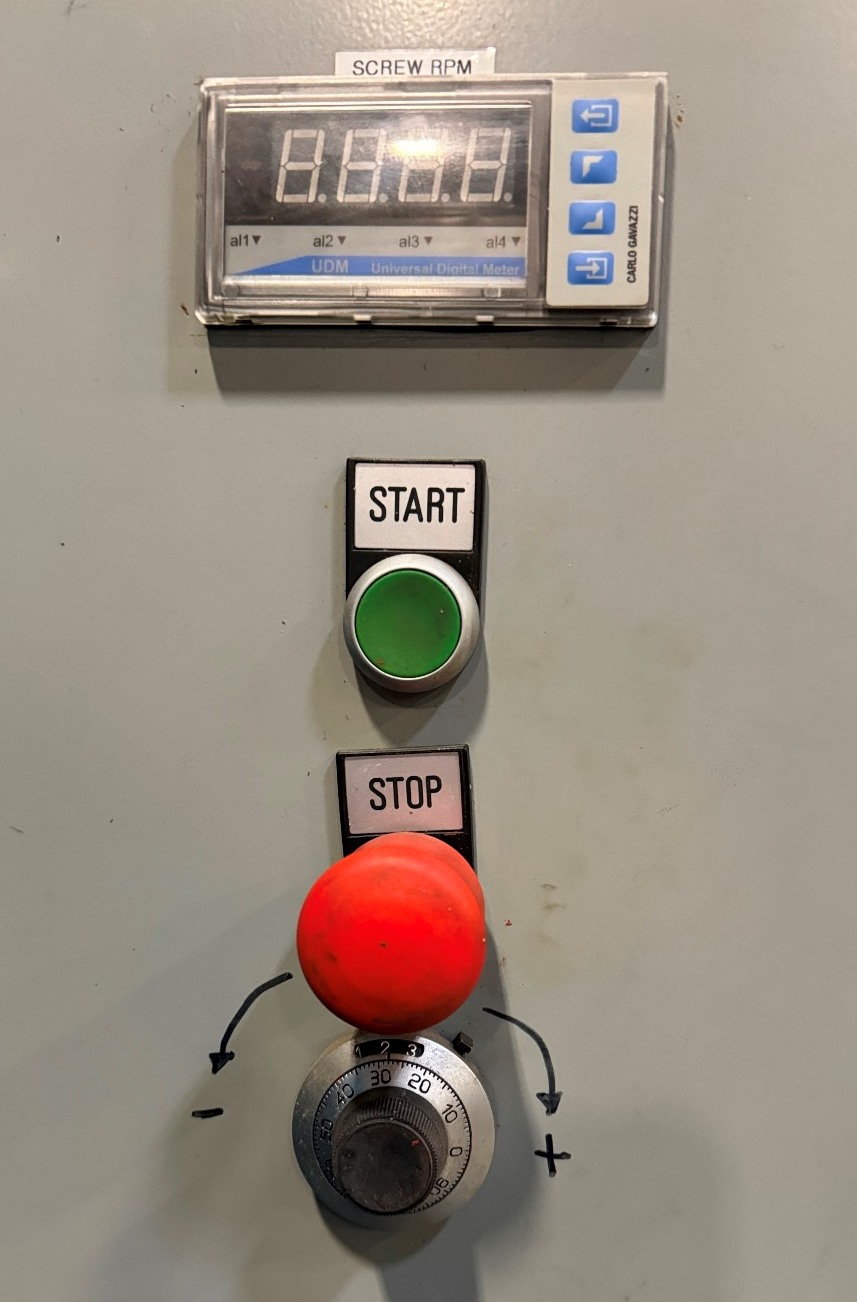

- operator controls with RPM gauge, stop, emergency pushbutton, etc.

- unitized base

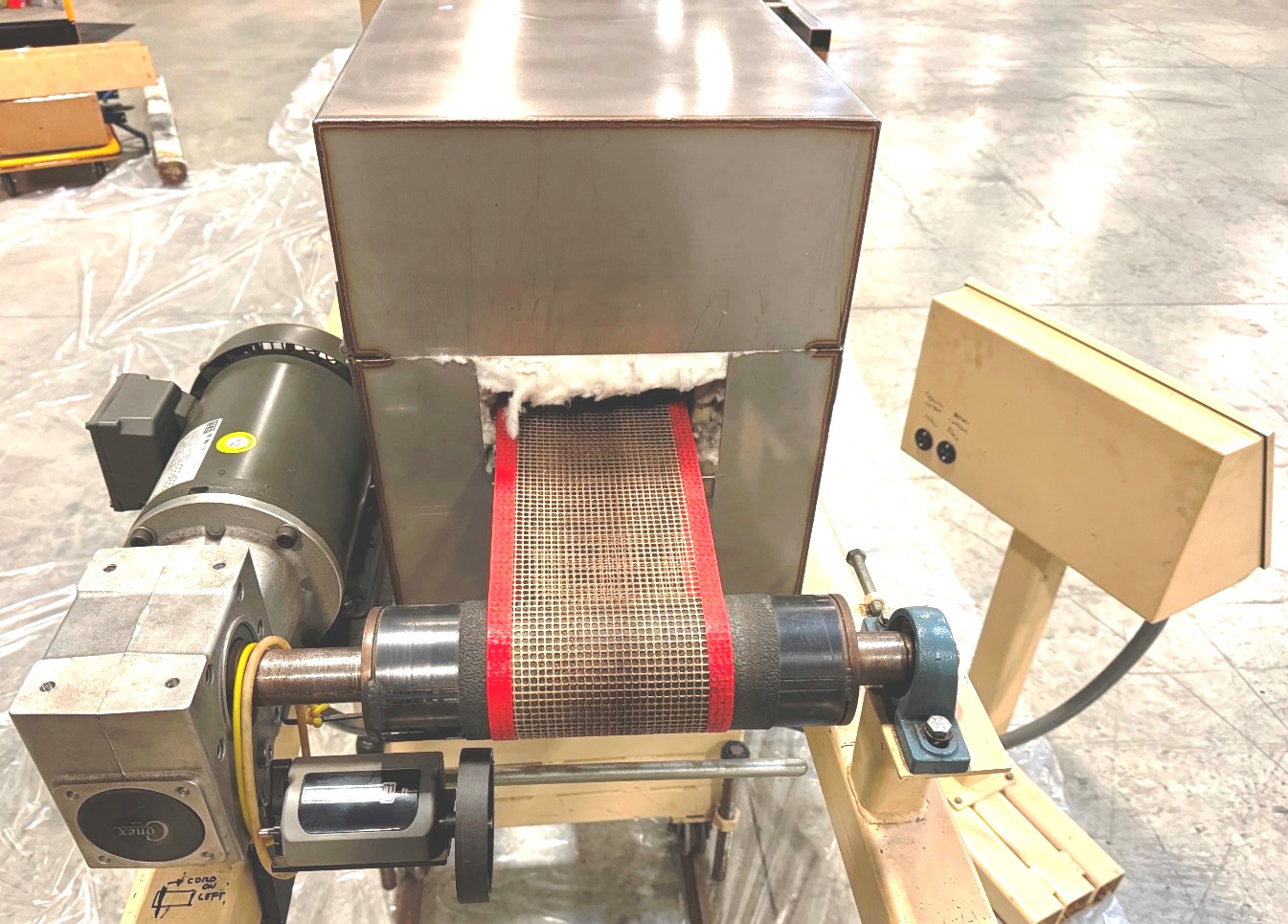

- Continuous silicone curing oven with two heating zones

- First zone: high temperature @ 1400°F, 3’ long

- Second zone: lower temperature @ 600°F, 10’ long, 6” high temp fabric conveyor belt, etc

- Electric Infrared Heating

- Stainless steel inner & outer enclosures w/ high temperature insulation

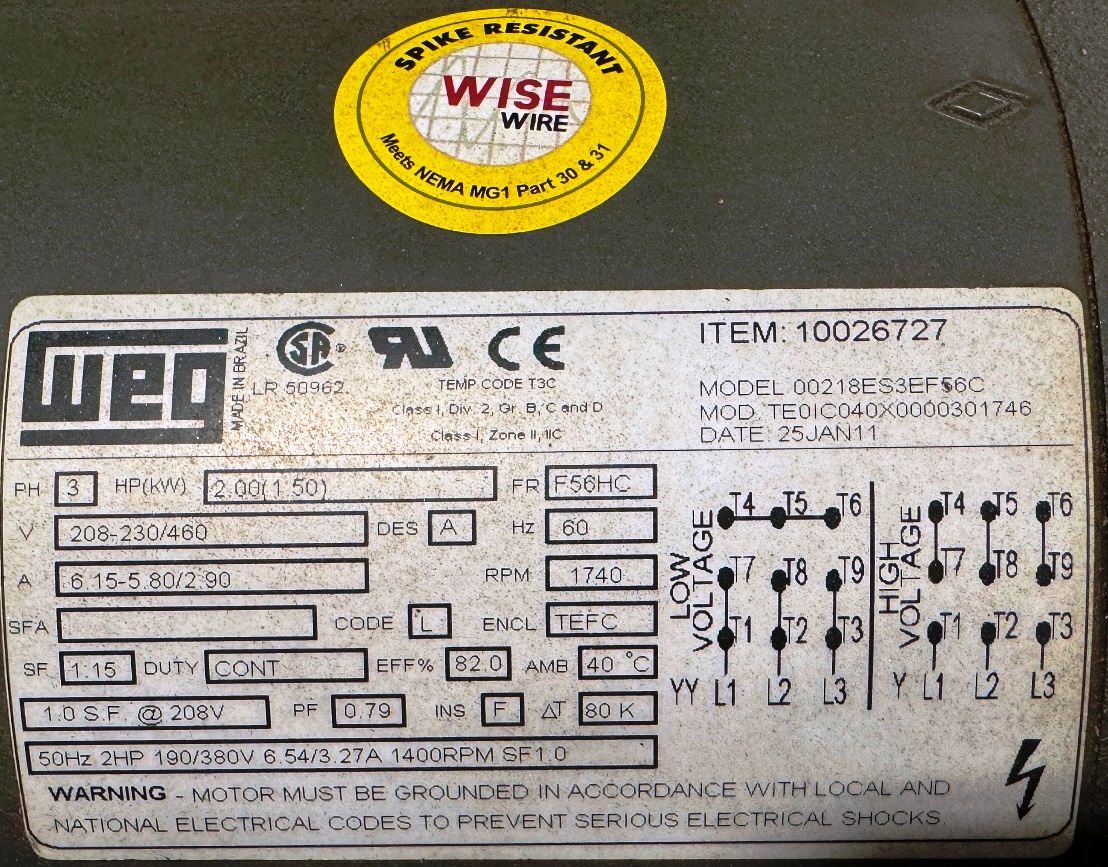

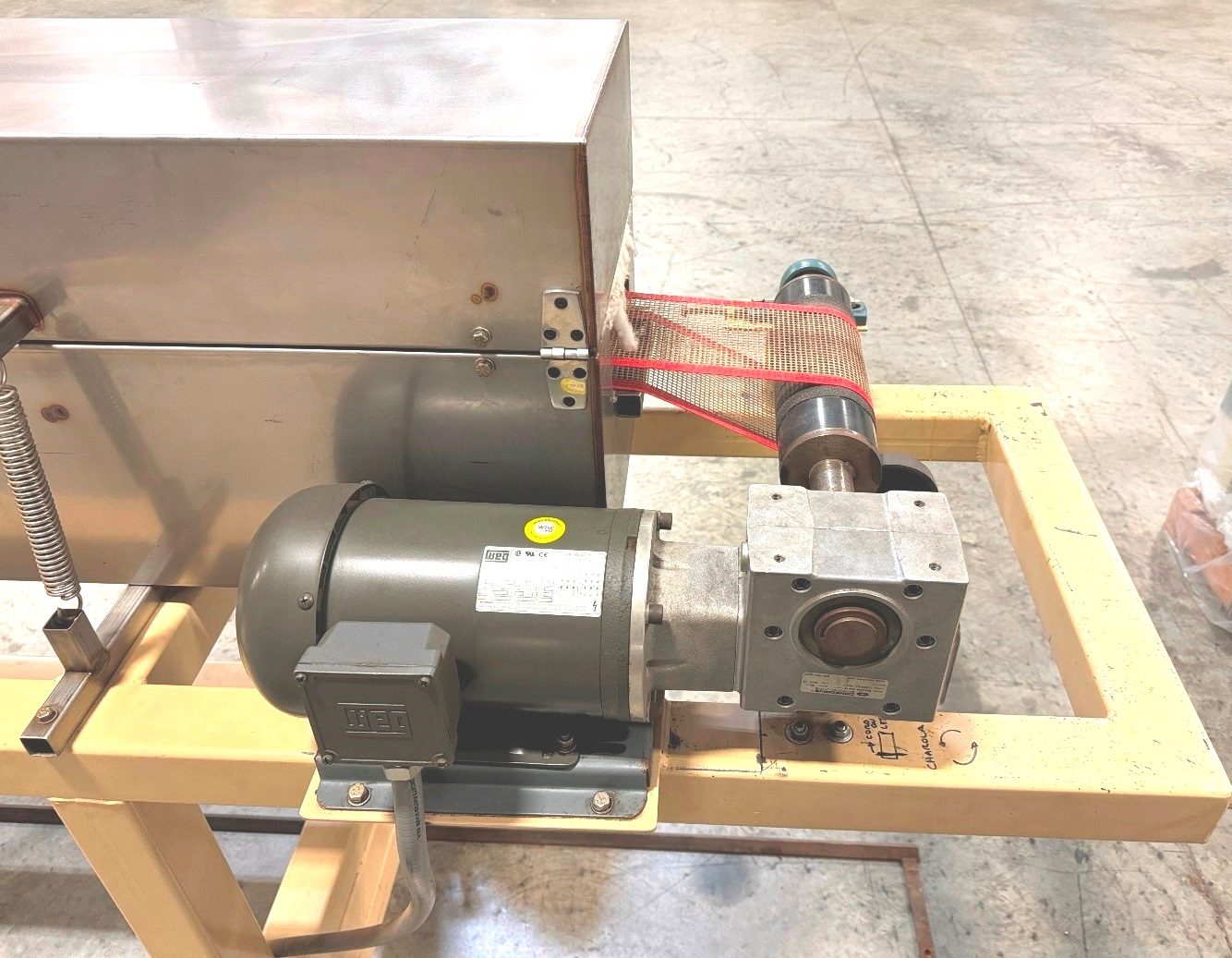

- 1HP/0.75KW variable speed conveyor motor & AC inverter drive

- Conveyor Speed: 20-780 IPM (0.5-20m/min)

- Base on rollers and with adjustable feet for easy height setting & installation

- 480V/3PH